- infor1@fiberglassyn.com

- +86-13933702587

Niumaterial Glass Fiber:

Building Future's Infrastructure

Corrosion Resistance · 50+ Year Lifespan · Lightweight Design

Niumaterial Solutions: Reinforcing Civil Engineering

Structural Reinforcement · Pipe Networks · Modular Construction

Infrastructure includes manhole covers, public facilities and amusement facilities, which require corrosion-resistant and highly durable materials. Glass fiber composite materials are widely used in manhole covers, gratings, swimming pools, park benches, theme park amusement facilities due to their light weight and high strength, with a service life of more than 50 years.

Core products include fiber chopped, fiberglass smc roving, direct roving, chopped strand mat, woven roving, spray up roving, which meet ASTM/ISO standards, reduce maintenance costs and improve safety.

Fiberglass Innovations: Redefining Home Appliances & Sanitary Solutions

Lighter · Stronger · Longer-Lasting – Fiberglass Elevates Performance & Quality

Manhole covers

During the production process, are you facing the following challenges:

- Heavy steel hulls increase fuel consumption and corrosion risks.

Niumaterial provides you with glass fiber solution optimized products:

fiberglass Products

Fiberglass Chopped Strand Mat、Fiberglass Surface Mat、Fiberglass Combo Mat、Fiberglass Woven Roving

grilles

During the production process, are you facing the following challenges:

- Traditional repair materials degrade rapidly in harsh marine environments.

Niumaterial provides you with glass fiber solution optimized products:

fiberglass Products

Fiberglass Axial Cloth、Fiberglass Spray Up Roving、Fiberglass Chopped Strand Mat、Fiberglass Woven Roving

swimming pools

During the production process, are you facing the following challenges:

- Metal parts limit fuel efficiency and design flexibility.

Niumaterial provides you with glass fiber solution optimized products:

fiberglass Products

Fiberglass smc roving、Continuous Mat、Fiberglass Chopped Strand Mat

amusement facilities

During the production process, are you facing the following challenges:

- High-temperature exhaust gases degrade conventional materials.

Niumaterial provides you with glass fiber solution optimized products:

fiberglass Products

Fiberglass Needle Mat

Niumaterial's Fiberglass Solutions - Your Production Challenges

Niumaterial’s Fiberglass technologies that transform material challenges into quality excellence

Fiberglass Chopped Strand Mat

A non-woven material made of randomly oriented glass fibers (25-50mm length), bonded with resin-compatible binder. Ideal for hand lay-up, molding, and corrosion-resistant layers in marine/auto parts. Lightweight, high strength, and easy to shape.

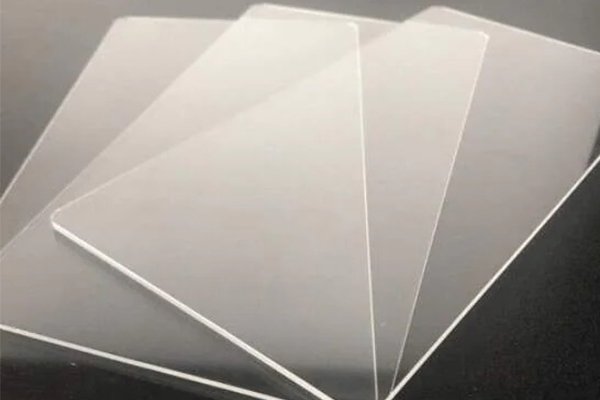

fiberglass Surface mat

Fiberglass surface mat is an ultra-thin nonwoven reinforcement made of C-glass or E-glass fibers, with weights ranging 30/50gsm. As the outermost layer of composites, it effectively conceals fiber patterns to deliver Class-A finish, while improving resin flow and anti-penetration properties

fiberglass woven roving

Fiberglass woven roving is a high-strength reinforcement material available in plain, twill, and satin weaves. Plain weave offers balanced biaxial strength, twill weave suits complex contours, while satin weave delivers high strength with smooth surfaces.

Fiberglass Combo Mat

Fiberglass combo mat is a composite material with a wide range of uses. It consists of multiple layers of glass fiber strands and binders. These layers are usually arranged in a specific pattern. A layer of roving is sandwiched between two layers of chopped strand mat, combining the advantages of chopped strand mat and roving.

Fiberglass Axial Cloth

A multi-layer fabric with fibers oriented at ±45°, 0°, 90° for structural reinforcement. Used in marine hulls, wind blades, and auto parts. High impact resistance, delamination-proof, and ISO 12215 compliant.

Fiberglass Spray Up Roving

Fiberglass spray up roving is a reinforcement material used in the jetting process, a common method for manufacturing fiberglass composite parts. One of its main advantages is its excellent mechanical properties, providing high tensile strength, stiffness and impact resistance to the final composite product.

Fiberglass Needle Mat

High silica needle mat is made of fine E glass fiber through a needle mat production machine. The tiny gaps formed during the production process give the product excellent thermal insulation performance. The insulation and electrical properties of E glass without binder make High silica needle mat an excellent and environmentally friendly product in the field of insulation materials.

fiberglass smc roving

Fiberglass smc roving is a versatile material that is cut to length (25mm) in the manufacture of smc sheets and dispersed in a resin paste, combining the strength and durability of fiberglass with the ease of processing of thermosetting resins sex.

Unique Features And Fiberglass Molding Process Solutions

Providing winding, pultrusion, compression molding and other processes, Niumaterial accurately meets diverse product needs.

Customer selection rate

84%

A continuous method to produce linear composites: fibers → resin impregnation → pre-forming → cure in heated die → pulled to final shape. Ideal for structural profiles (ladders, rods) with high strength & corrosion resistance.

Customer selection rate

90%

A method to shape composites: pre-impregnated materials → heated mold → high pressure → cure → demold. Ideal for complex parts (auto components, enclosures) with high precision and mass production efficiency.

Customer selection rate

85%

Fiberglass panel roving has excellent thermal insulation properties, and the inherently low thermal conductivity of fiberglass minimizes heat transfer, making it suitable for applications where temperature control is critical, such as building insulation or refrigeration.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

Contact Us

86-13933702587

Email Us

infor1@fiberglassyn.com