- infor1@fiberglassyn.com

- +86-13933702587

23 Years Of Experience In

Fiberglass Woven Roving Production

Provide you with reliable quality and innovative product solutions

Choosing The Right Fiberglass Woven Roving For Your Project

Niumaterial versatile fiberglass woven roving can meet the needs of your diverse projects, guaranteeing superior performance and cost-effectiveness.

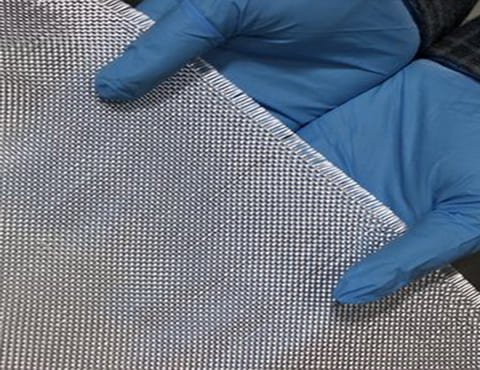

Plain Weave Fiberglass Woven Roving, providing balanced strength in the warp and weft directions, with good stability and dimensional control, suitable for applications requiring equal strength in both directions, such as general reinforcement, laminates and repairs.

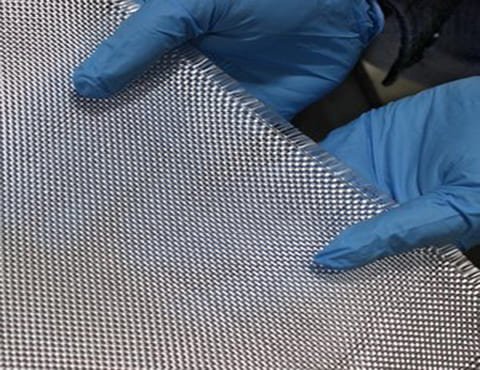

Twill Weave Fiberglass Woven Roving, which has higher strength and impact resistance than plain weave, conforms to complex shapes and contours, and is suitable for high strength and weight applications such as shipbuilding, automotive parts and wind turbine blades.

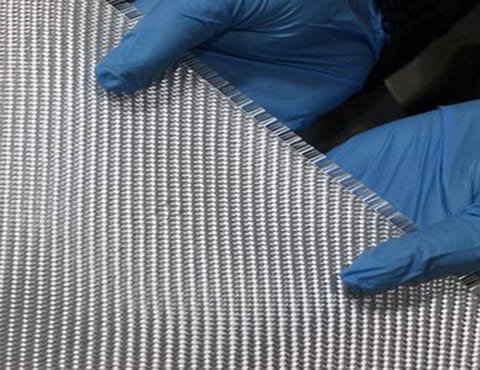

Satin Weave Fiberglass Woven Roving features a more intricate pattern with excellent drape, fit and flexibility.Ideal for applications requiring a smooth surface finish, high strength and light weight, such as aerospace components, high-end sports equipment and decorative laminates.

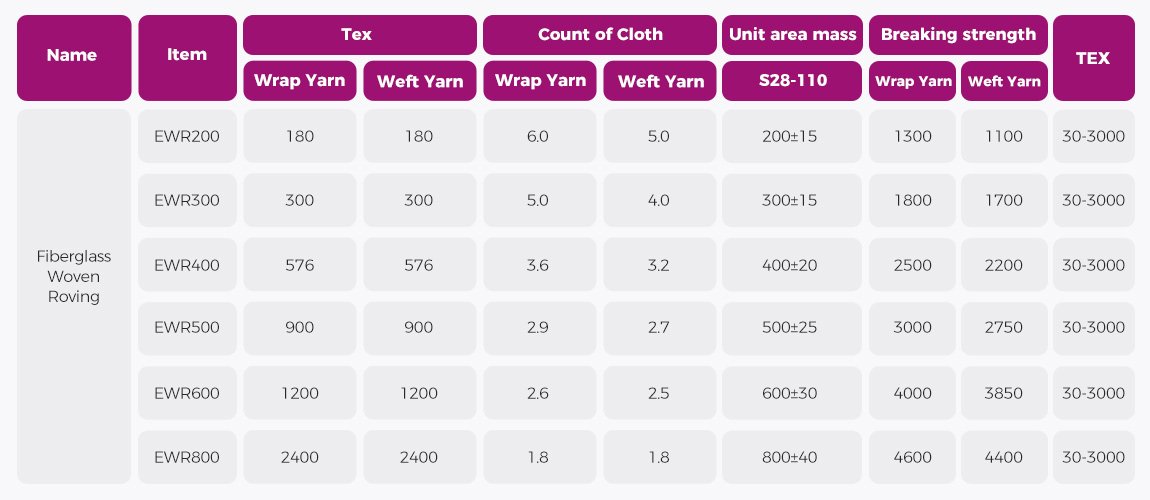

Find The Best Specification For Your Project

Niumaterial fiberglass woven roving are available in a variety of gauges, enabling you to precisely match your project

ensuring optimum performance and meeting your specific needs.

Fiberglass Woven Roving TDS/MSDS

Contact Niumaterial to obtain product test reports, TDS, and MSDS downloads.

Fiberglass Woven Roving For Meet Your Diverse Project Needs

Whether you are using it for shipbuilding, swimming pool manufacturing

or other industries such as winding pipe, FRP enhanced, etc., Niumaterial is your ideal choice.

Niumaterial Fiberglass Woven Roving is widely used in pipe production. It has high strength and uniform weaving, which can ensure the tightness and uniform thickness of the cloth during the winding process and improve the overall quality and stability of the pipe.

Recommended Specifications

Small Width 20-30cm, 500-600gsm Epoxy Resin

Niumaterial Fiberglass Woven Roving can improve the structural strength of the hull, reduce weight, have good corrosion resistance, and has the advantages of design flexibility and easy processing and installation.

Recommended Specifications

400gsm, 600gsm

Polyester Resin

Niumaterial Fiberglass Woven Roving has excellent properties such as acid and alkali resistance, corrosion resistance, and weather resistance; it can be completely soaked when combined with resin and has a smooth surface; it is widely used in FRP reinforced materials.

Recommended Specifications

400gsm, 600gsm

Polyester Resin

Fiberglass Woven Roving is used to enhance the structural integrity of swimming pool surfaces, making them strong and durable, and is often applied with resin to form a composite material that is waterproof and provides excellent strength and stability.

Recommended Specifications

400gsm, 600gsm

Polyester Resin

Unique Features And Benefits Of Fiberglass Woven Roving

That’s why Niumaterial fiberglass woven roving can meet the unique needs of different industries or project target audiences.

Complete project

79%

Fiberglass rovings have excellent tensile strength while keeping the overall weight of the composite structure to a minimum, making Fiberglass woven roving particularly advantageous in applications requiring a lightweight yet strong material.

Complete project

90%

Fiberglass woven roving are known for their excellent impact resistance. Its interlaced weave structure effectively disperses and absorbs energy, making it highly resilient to sudden shocks or external forces.

Complete project

85%

Fiberglass woven roving is their high resistance to chemicals, a property that makes them suitable for applications requiring exposure to corrosive substances, maintaining structural integrity and extending the life of the composite.

Complete project

95%

Niumaterial advanced manufacturing processes and quality control measures ensure that the composition and structural integrity of each woven roving roll remains consistent, with unparalleled uniformity in fiber distribution and thickness

Complete project

85%

The precise manufacturing process and optimized fiber distribution of Niumaterial Fiberglass woven roving make the woven roving have a smooth surface, minimize the occurrence of fiber print-through, and improve the overall aesthetics and quality of the final product.

Complete project

90%

Niumaterial products are manufactured using a precise and controlled process which ensures that each roll of woven roving contains a high concentration of premium glass fibers which results in superior reinforcement and enhanced mechanical properties.

Customized To Your

Unique Needs

Niumaterial understands that every project and application is unique, turning your vision into reality with tailor-made fiberglass woven roving solutions.

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Niumaterial offer a range of product customization options to ensure our products meet your specific needs.

Including weight per unit area, width and length, weave patterns, special specification customization, and more.

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

+86-139 3370 2587

Email Us

fiberglassnicole@gmail.com