- infor1@fiberglassyn.com

- +86-13933702587

23 Years Of Experience In

Fiberglass Chopped

Strands For Brake Pads Production

Provide you with reliable quality and innovative product solutions

Fiberglass Chopped Strands For Brake Pads

Niumaterial offer CE-compliant, versatile, and customizable Fiberglass Chopped Strands For Brake Pads to help you build your project.

Fiberglass chopped strands for brake pads is a special reinforcement material used in the production of high performance brake pads. These chopped strands are made from high-quality fiberglass filaments that are chopped to specific lengths and then incorporated into brake pad formulations.

The application of fiberglass chopped strands in brake pads is mainly to improve the strength, durability and heat resistance of brake pads, and enhance their mechanical strength and use characteristics. These properties make fiberglass an ideal reinforcement material for the manufacture of high-quality brake pads, capable of meeting the demanding requirements of modern braking systems.

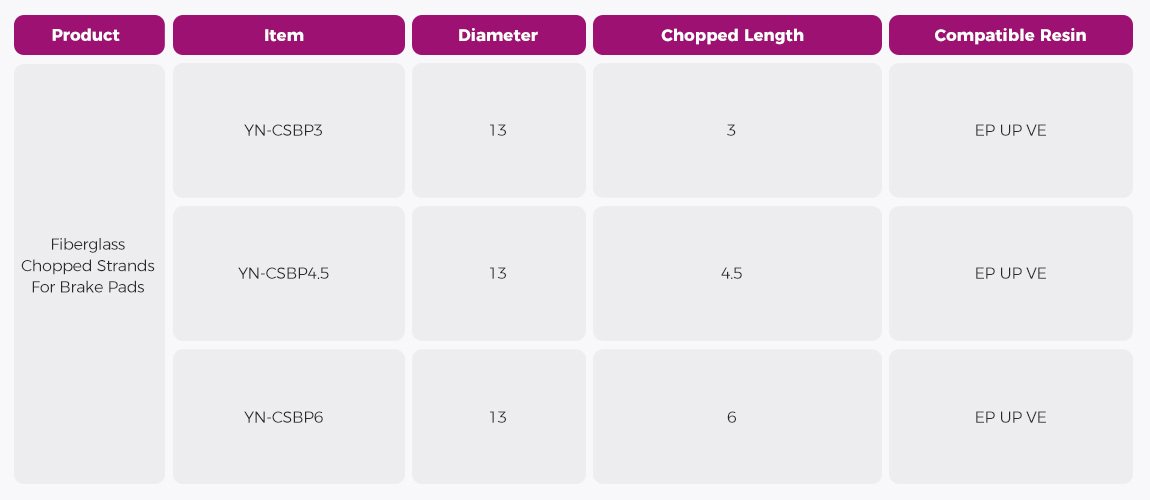

Find The Best Specification For Your Project

Niumaterial fiberglass chopped strands for brake pads are available in a variety of gauges, enabling you to precisely match your project

ensuring optimum performance and meeting your specific needs.

Chopped Strands For Brake Pads For Meet Your Diverse Project Needs

Whether you are using for friction materials, brake pads, heavy machinery

or other automakers, Niumaterial can provide products to meet your specific needs.

Fiberglass chopped strands are used in the production of various friction materials, helping to improve the friction performance, heat resistance and wear resistance of linings and facings, ensuring reliable performance in automotive and industrial applications.

Recommended Specifications

3mm、4.5mm

Fiberglass chopped strands are incorporated into brake pad formulations to enhance their mechanical properties and also help improve the pad’s heat resistance and dimensional stability, ensuring effective braking performance and long-term durability.

Recommended Specifications

3mm、4.5mm

Fiberglass chopped strands are used in various automotive components related to braking systems, including brake shoes, brake discs and brake drums, reinforcing these components to improve their structural integrity and resistance to mechanical stress.

Recommended Specifications

3mm、4.5mm

Unique Features And Benefits Of Chopped Strands For Brake Pads

Niumaterial versatile fiberglass chopped strands for brake pads can meet the needs of your diverse projects, guaranteeing superior performance and cost-effectiveness.

Complete project

79%

Fiberglass chopped strands have excellent tensile strength and are ideal for reinforcing brake pads. These chopped strands provide additional structural integrity and help improve the overall durability of brake pads.

Complete project

90%

Brake pads are subject to high temperatures during braking, fiberglass chopped strands have excellent heat resistance, they can withstand the heat generated during braking without deformation or loss of strength.

Complete project

85%

Brake pads are subject to great force and impact during operation, the use of fiberglass chopped strands enhances the impact resistance of the pad, allowing it to withstand sudden impacts and prevent premature failure, minimizing breakage or damage risks of.

Complete project

95%

Niumaterial uses advanced manufacturing technology to achieve controlled fiber dispersion within the chopped strands, which ensures that the fibers are evenly distributed throughout the brake pad, minimizing the risk of localized weakness.

Complete project

85%

Niumaterial fiberglass chopped strands are engineered for superior bonding properties, and they have enhanced compatibility with a variety of adhesives used in brake pad manufacturing to enhance adhesion and reduce delamination.

Complete project

90%

Niumaterial employ specific additives and surface treatments to enhance the abrasion resistance of its fiberglass chopped strands, prolonging the life of the brake pads, minimizing the need for frequent replacement and reducing maintenance costs.

Customized To Your

Unique Needs

Niumaterial understands that every project and application is unique, turning your vision into reality with tailor-made fiberglass chopped strands for brake pads solutions.

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Niumaterial offer a range of product customization options to ensure our products meet your specific needs.

Including fiber length, sizing compatibility,special specification customization, etc.

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

+86-139 3370 2587

Email Us

fiberglassnicole@gmail.com