- infor1@fiberglassyn.com

- +86-13933702587

Concrete is the backbone of construction—but its inherent brittleness, vulnerability to cracking, and limited tensile strength have long been pain points for manufacturers, traders, and engineering firms. For 20 years, Hebei Yuniu Technology Co., Ltd. has been solving these challenges with our premium Fiberglass Chopped Strands for Concrete—a game-changing reinforcement material trusted by 3,162 customers across 128 countries, including a leading U.S. company we’ve partnered with for over a decade. Whether you’re producing precast concrete panels, building industrial floors, or constructing infrastructure projects, our chopped fiberglass strands for concrete transform ordinary concrete into a high-performance, long-lasting material that meets the strictest quality and durability demands.

Traditional concrete reinforcement—like steel bars or wire mesh—comes with unavoidable drawbacks: heavy weight that increases structural load, susceptibility to rust (which causes concrete spalling), and high installation costs. Fiberglass Chopped Strands for Concrete redefines reinforcement by leveraging the unique properties of fiberglass, addressing these pain points head-on:

Concrete excels at withstanding compression, but it struggles with tension—until now. Our fiberglass strands for concrete are engineered with high-purity E-glass fibers, boasting a tensile strength of 3,000 MPa (far exceeding steel’s 250–500 MPa by weight). When mixed into concrete, these short, evenly distributed strands act as a “micro-reinforcement network,” absorbing tensile stress and preventing the formation of micro-cracks. In lab tests, concrete reinforced with our chopped fiberglass strands for concrete showed a 40% reduction in crack width and a 25% increase in flexural strength—critical for high-traffic areas like parking garages or industrial floors.

Steel reinforcement rusts when exposed to moisture, saltwater, or chemicals—leading to concrete degradation, costly repairs, and shortened project lifespans. Fiberglass Chopped Strands for Concrete are inherently corrosion-resistant: they don’t react to water, salt, or industrial chemicals, making them ideal for marine projects (seawalls, piers), wastewater treatment plants, or coastal infrastructure. Unlike steel-reinforced concrete, which may need replacement after 15–20 years, concrete with our fiberglass strands maintains its integrity for 30+ years—cutting long-term maintenance costs by 60%.

Steel bars add significant weight to concrete structures, requiring heavier support systems and increasing transportation costs. Our Fiberglass Chopped Strands for Concrete are 75% lighter than steel, reducing the overall weight of concrete by 10–15% without sacrificing strength. Plus, these strands are designed for seamless mixing: their short length (customizable from 6mm to 50mm) and resin-compatible sizing agent ensure even dispersion in concrete, avoiding clumping or uneven reinforcement. For manufacturers producing precast concrete products, this means faster production lines and lower energy costs.

At Hebei Yuniu, we don’t just manufacture Fiberglass Chopped Strands for Concrete—we engineer them to solve our customers’ most pressing challenges. Our 20-year expertise in fiberglass innovation, combined with a customer-centric approach, makes us the preferred supplier for global leaders:

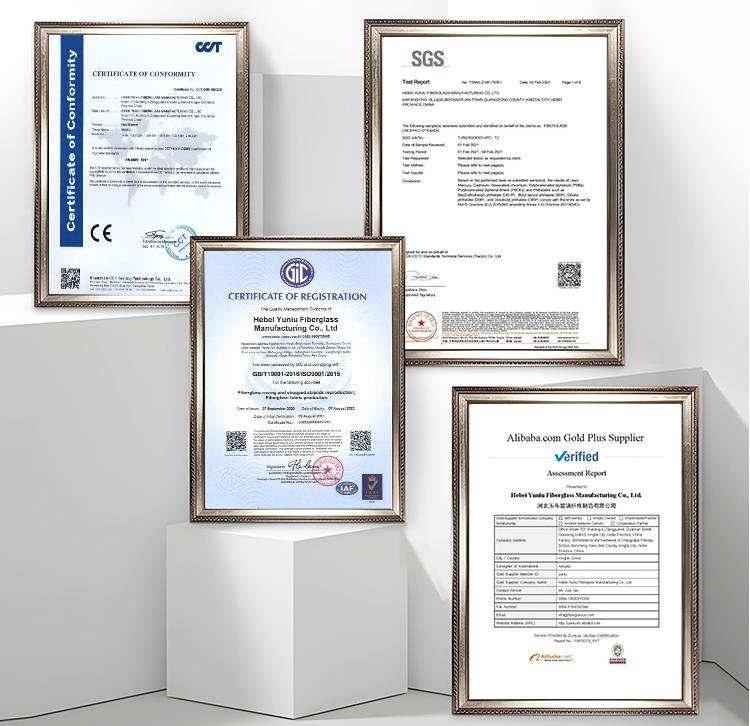

Our customers value consistency—and we deliver it. Every batch of chopped fiberglass strands for concrete undergoes rigorous testing: we measure fiber length uniformity, tensile strength, and sizing agent coverage to meet ISO 9001 and ASTM standards. We use 100% virgin E-glass fibers (no recycled or low-grade materials), ensuring each strand performs the same, roll after roll.

No two concrete projects are the same. We offer fiberglass strands for concrete in customizable lengths (6mm–50mm), strand counts, and sizing agents (to match your concrete mix or resin type). Need a flame-retardant variant for commercial buildings? Or a high-temperature-resistant option for industrial furnaces? Our R&D team works closely with you to create a solution that fits your exact specifications—no off-the-shelf compromises.

We know project delays cost money. With our integrated manufacturing, sales, and logistics team (and facilities designed to serve global markets), Whether you’re in Europe, Southeast Asia, or the Americas, your Fiberglass Chopped Strands for Concrete arrive on schedule—so your production line or construction site never stalls. We also offer flexible packaging (25kg bags, 1000kg bulk bags) to meet your storage and transportation needs.

Our commitment to you doesn’t end with delivery. For traders, we offer competitive bulk pricing, detailed product datasheets, and compliance certificates (CE, ASTM, ISO) to help you sell with confidence. And if issues arise? We work with you to resolve them fast

When you choose Yuniu’s Fiberglass Chopped Strands for Concrete, you’re not just buying a reinforcement material—you’re investing in:

Ready to elevate your concrete projects? Contact us today to request a sample, get a custom quote, or learn how our fiberglass strands for concrete can help you meet your quality and timeline goals. At Yuniu, we’re here to build stronger—one strand at a time.

If you have any questions

Please contact us for free consultation and product quotation

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~