- infor1@fiberglassyn.com

- +86-13933702587

In modern industry, winding pipes are widely used in petroleum, chemical industry, municipal engineering and other fields due to their excellent mechanical properties and durability. Choosing the right reinforcement material is essential to ensure the quality and long-term stability of winding pipes. As a high-performance reinforcement material, fiberglass woven fabric has become the first choice for manufacturing winding pipes due to its excellent strength, corrosion resistance and ease of construction. This article will explore in depth the application and advantages of fiberglass woven fabric in winding pipes, and introduce how Niumaterial, as an industry-leading manufacturer, can provide you with a perfect solution.

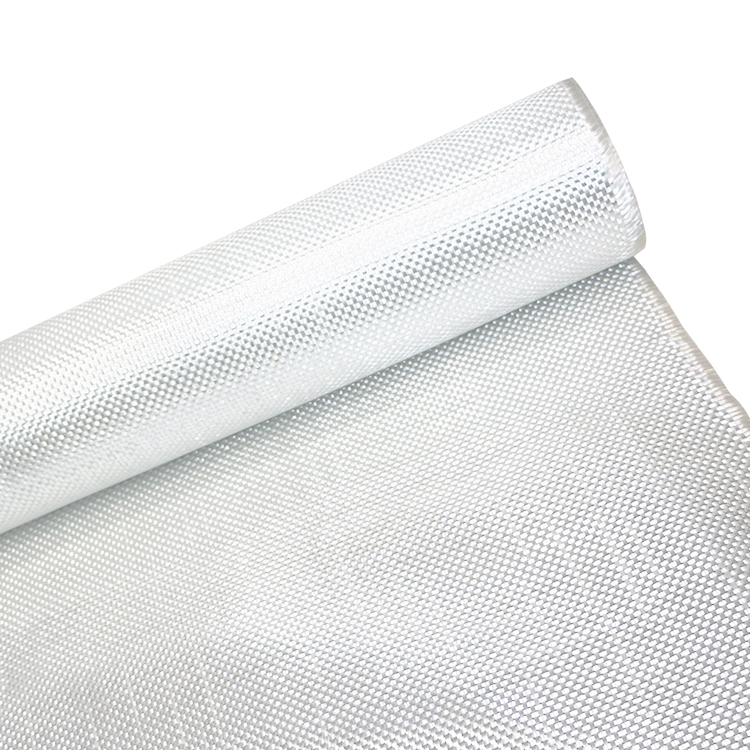

Fiberglass woven roving is a fabric made of high-strength glass fiber filaments crisscrossed to form a regular grid structure. This structure gives the woven fabric excellent mechanical properties and uniform distribution characteristics, ensuring that it can effectively disperse stress and prevent cracking and deformation during use. Fiberglass woven fabric is not only lightweight and high-strength, but also able to maintain stable performance in various harsh environments.

A spiral wound pipe is a composite material pipe made by a continuous winding process, which is usually used to transport liquids, gases and other media. In order to ensure the strength and durability of the pipe, reinforcement materials need to be added inside or outside the pipe. As a high-performance reinforcement material, glass fiber woven fabric is widely used in the manufacturing process of spiral wound pipes to provide additional structural support and protective layers.

Direct yarn refers to unprocessed glass fiber filaments with extremely high tensile strength and good flexibility. In the manufacturing process of spiral wound pipes, direct roving can be combined with other materials (such as resin) to form a strong composite structure. The following are the specific applications of direct yarn in spiral wound pipes:

Chopped strand mat is a thin sheet material formed by randomly arranging and bonding chopped glass fiber strands. It has good permeability and uniform distribution characteristics, and can quickly combine with resin to form a strong composite structure. The following are the specific applications of chopped strand mat in winding pipes:

As a high-performance reinforcement material, glass fiber woven cloth has the following significant advantages:

The high strength characteristics of fiberglass woven fabric enable it to significantly improve the overall strength of the wound pipe. This not only enhances the bearing capacity of the pipeline, but also effectively prevents the pipeline from cracking and deformation during transportation and use. Especially for high-pressure transmission pipelines, the reinforcing effect of fiberglass woven fabric is particularly important.

Glass fiber woven roving has excellent durability and corrosion resistance, and can maintain its performance for a long time in various harsh environments. This not only extends the service life of the pipeline, but also reduces maintenance costs. Especially in complex environments such as chemical plants and sewage treatment facilities, the protective effect of glass fiber woven fabric is particularly obvious.

Glass fiber woven fabric is easy to cut and install, and can be quickly laid on the surface of the pipeline, reducing construction time and labor costs. Especially in large-scale engineering projects, an efficient construction process can significantly reduce the overall project cost.

The production process of glass fiber woven roving meets international environmental standards, uses environmentally friendly materials, and reduces VOC emissions. This not only helps protect the environment, but also meets the sustainable development requirements of modern construction and industrial fields.

As an industry-leading manufacturer, Niumaterial has launched glass fiber woven roving with unique advantages with its excellent quality and innovative technology. Here are a few key reasons that highlight Niumaterial’s unique advantages over other manufacturers:

Niumaterial strictly follows international quality standards to ensure that each batch of products reaches the highest level. The company has passed multiple certifications, including ISO 9001 quality management system certification, ASTM D3039 composite material tensile performance test standard and EN 13501-1 fire performance test standard.

With more than 20 years of technical accumulation and market experience, Niumaterial is well aware of customer needs and can provide the most appropriate solutions. It provides more than 1,000 tons of procurement services to more than 100 companies around the world each year, and is widely used in building reinforcement, pipeline repair and decoration and other fields.

Niumaterial has a professional technical team that can provide comprehensive technical support during the design, production and installation process to ensure that customers can fully utilize the advantages of the product. In addition, the company also provides comprehensive after-sales service to promptly solve problems encountered by customers and ensure the long-term and stable operation of the project.

In summary, fiberglass woven cloth has become the preferred material for manufacturing wrapped pipes due to its excellent strength, durability and corrosion resistance. Whether it is to improve pipe strength, extend service life or improve construction efficiency, fiberglass woven cloth performs well. As a leading manufacturer in the industry, Niumaterial provides you with perfect solutions with its excellent quality and innovative technology. I hope this article can provide you with valuable references and help you make a wise choice. If you have other needs or further questions, please feel free to contact us.

This article provides detailed background information and technical guidance through a comprehensive analysis of the application of fiberglass woven cloth in wrapped pipes, helping readers understand and choose the most suitable type of woven cloth. At the same time, the article highlights the advantages of Niumaterial woven cloth and demonstrates its importance in modern industry. Through a systematic structure and detailed data support, this article not only answers readers’ questions, but also demonstrates Niumaterial’s leading position in the field of woven cloth.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a header to begin generating the table of contents Big 5 Global – Connecting the Future of Global Construction As a

Table of Contents Add a header to begin generating the table of contents Introduce In the composite materials sector, where strength, versatility and reliability are

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~