- infor1@fiberglassyn.com

- +86-13933702587

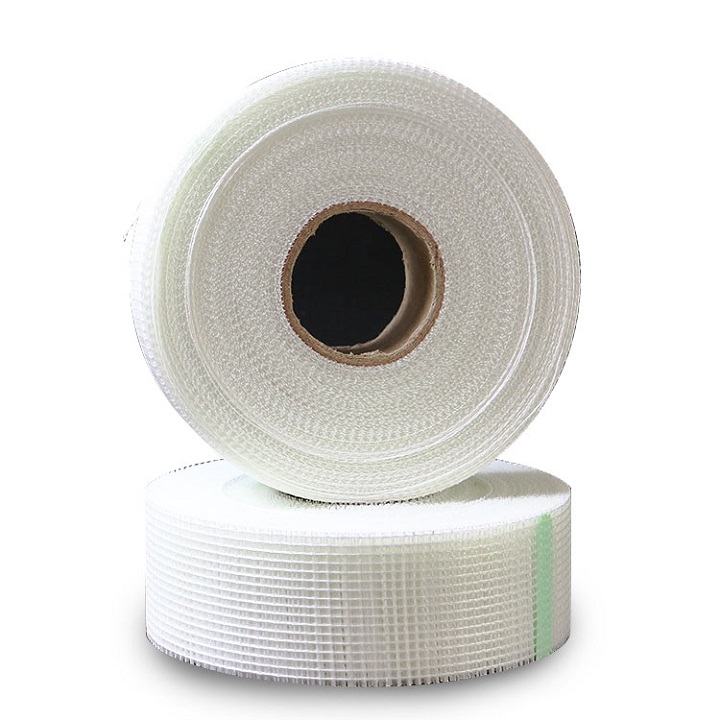

In the construction and decoration industry, plasterboard repair and wall joint treatment are two common and important application areas. Whether it is a new project or an old house renovation, it is crucial to ensure the flatness, stability and aesthetics of the wall. As a high-performance material, fiberglass self-adhesive tape plays an important role in these applications due to its excellent mechanical properties and durability. This article will introduce in detail why fiberglass self-adhesive tape is chosen instead of traditional materials, and explore key issues such as its heat resistance, tensile properties, and service life, and finally help readers understand how to choose the self-adhesive tape that best suits the project.

Although traditional materials such as paper tape or ordinary fabric tape have lower costs, their tensile strength and durability are far inferior to fiberglass self-adhesive tape. Fiberglass self-adhesive tape is woven from high-strength glass fibers, has extremely high tensile strength and good flexibility, can effectively prevent wall cracking and deformation, and ensure long-term and stable use effects.

Fiberglass self-adhesive tape has good tolerance to chemicals such as acids and alkalis, and can maintain its performance in various harsh environments. In contrast, traditional materials are prone to aging and failure in humid, high or low temperature environments, affecting their service life and reliability.

The surface of the fiberglass self-adhesive tape is evenly coated with a special self-adhesive emulsion, which can easily adhere to any smooth or rough surface, reducing labor costs and time consumption. Traditional materials require additional adhesives or other auxiliary tools, and the construction process is relatively complicated.

Glass fiber self-adhesive tape can be perfectly combined with a variety of decorative materials to enhance the overall aesthetic effect and facilitate subsequent painting and decoration. Traditional materials are often not as aesthetically pleasing as fiberglass self-adhesive tape, especially when applied over a large area.

The heat resistance of fiberglass self-adhesive tape depends on the type of adhesive used and its formula. Niumaterial self-adhesive tape uses an advanced adhesive formula to ensure that it maintains good adhesion over a wide temperature range. The following are specific heat resistance characteristics:

The adhesive of Niumaterial self-adhesive tape is specially designed to maintain stable adhesion under high temperature conditions. For example, in a high temperature environment of +80°C, Niumaterial self-adhesive tape can still maintain good adhesion, which is suitable for high temperature environments such as indoor heating pipes, kitchens and bathrooms.

Niumaterial self-adhesive tape not only performs well at high temperatures, but also maintains stable performance in low temperature environments. For example, in low temperature conditions of -40°C, Niumaterial self-adhesive tape can still provide reliable adhesion, which is suitable for construction projects in cold northern regions.

According to third-party laboratory tests, Niumaterial self-adhesive tape can still maintain stable adhesion in the temperature range of -40°C to +80°C, which is suitable for construction in various climate conditions. This wide temperature adaptability makes it an ideal repair and reinforcement material.

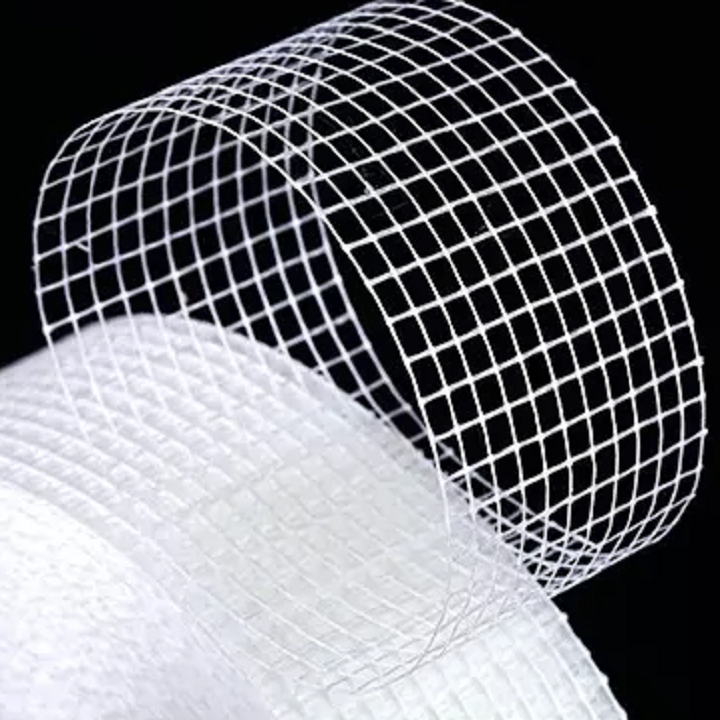

Fiberglass tape itself has certain flexibility and tensile properties, but this does not mean that it can be stretched as much as rubber. Specifically:

Fiberglass tape can be stretched within a certain range, usually 5%-10% of its original length. This moderate stretching property enables it to adapt to slight stress changes, preventing crack expansion and wall deformation.

Although fiberglass tape has certain tensile properties, its main advantage lies in its extremely high tensile strength. This means that it can maintain structural integrity under large tensile forces and will not break or tear easily.

According to third-party laboratory tests, the tensile strength of Niumaterial’s fiberglass self-adhesive tape can reach more than 250 MPa, which is 20% higher than the industry average. For example, in actual applications, Niumaterial’s products can still maintain structural integrity under a pressure of 100 tons, far exceeding similar products.

The service life of self-adhesive fiberglass tape depends on multiple factors, including the quality of the materials used, the construction environment, and maintenance. Generally speaking, high-quality self-adhesive fiberglass tape can be used for more than 5 years or even longer under normal conditions. Especially in dry indoor environments, its service life can reach about 10 years.

High-quality self-adhesive fiberglass tape uses advanced adhesive formula and high-strength glass fiber to ensure that it maintains stable performance over a long period of time. Niumaterial self-adhesive tape excels in this regard and can provide long-term and reliable adhesion.

The construction environment has an important impact on the service life of self-adhesive tape. In dry indoor environments, self-adhesive tapes have a longer service life; while in humid, high or low temperature environments, more frequent maintenance and replacement may be required. Therefore, it is crucial to choose self-adhesive tapes suitable for specific environments.

Proper maintenance can extend the service life of self-adhesive tapes. For example, regular cleaning of the surface and avoiding exposure to extreme temperatures and chemicals can significantly increase its service life.

Self-adhesive fiberglass tape is an ideal choice for gypsum board repair. Its high strength and good flexibility can effectively prevent crack expansion and wall deformation, ensuring long-term stability of the repair area. In particular, alkali-resistant yarn (AR yarn) fiberglass tape is particularly suitable for cement-based material applications, such as reinforcement of gypsum board joints, due to its excellent alkali resistance.

During the installation of gypsum board, it is very necessary to use self-adhesive fiberglass tape to stick the wall joints. This not only prevents cracks at the joints, but also provides additional structural support to ensure the overall stability and aesthetics of the wall. Especially at the joints between new and old walls or where stress concentration is prone to occur, the use of self-adhesive fiberglass tape can significantly improve the durability and reliability of the wall.

In addition to gypsum board repair and wall joint treatment, self-adhesive fiberglass tape is also widely used in building reinforcement, crack repair, pipeline repair and other fields. Its excellent performance and versatility make it the preferred material for many projects.

As an industry-leading manufacturer, Niumaterial has launched fiberglass self-adhesive tape with unique advantages with its excellent quality and innovative technology. Here are a few key reasons that highlight Niumaterial’s unique advantages over other manufacturers:

Niumaterial strictly follows international quality standards to ensure that each batch of products reaches the highest level. The company has passed multiple certifications, including ISO 9001 quality management system certification, ASTM D3039 composite material tensile performance test standard and EN 13501-1 fire performance test standard.

With more than 20 years of technical accumulation and market experience, Niumaterial is well aware of customer needs and can provide the most suitable solutions. It provides more than 1,000 tons of procurement services to more than 100 companies around the world every year, which are widely used in building reinforcement, pipeline repair and decoration and other fields.

Niumaterial has a professional technical team that can provide comprehensive technical support during the design, production and installation process to ensure that customers can fully utilize the advantages of the product. In addition, the company also provides comprehensive after-sales service to solve problems encountered by customers in a timely manner and ensure the long-term and stable operation of the project.

Niumaterial is committed to reducing VOC emissions during the production process and adopts environmentally friendly materials in accordance with international environmental standards. The company has reduced energy consumption by 30% during the production process, further reducing its carbon footprint.

In order to meet the needs of different customers, Niumaterial provides fiberglass self-adhesive tapes in a variety of specifications and colors, and can be customized according to specific application scenarios. Whether it is special size, functional requirements or appearance decoration, it can be perfectly matched.

In summary, the selection of self-adhesive fiberglass tape suitable for gypsum board repair and wall joint treatment requires not only the performance of the material itself, but also the specific application scenarios and construction conditions. Fiberglass tape plays an important role in modern construction and decoration with its high strength, corrosion resistance and ease of construction. By clarifying needs, evaluating performance, referencing cases and consulting experts, you can choose the most suitable self-adhesive fiberglass tape. Niumaterial fiberglass self-adhesive tape has established a good reputation in the market with its excellent quality, rich experience and comprehensive services. Choosing Niumaterial means choosing professionalism, reliability and innovation. I hope this article can provide you with valuable reference and help you make a wise choice. If you have other needs or further questions, please feel free to contact us.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a header to begin generating the table of contents JEC World – The Global Innovation Hub for the Composites Industry JEC

Table of Contents Add a header to begin generating the table of contents Introduce In the world of construction, manufacturing, and engineering, the search for

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~