- infor1@fiberglassyn.com

- +86-13933702587

Niumaterial has supplied chopped fiberglass strands for concrete to over 100 precast concrete manufacturers worldwide. These manufacturers have successfully used our products to produce high-quality precast elements for projects ranging from residential buildings to large-scale infrastructure developments, attesting to the reliability and effectiveness of our strands in concrete reinforcement.

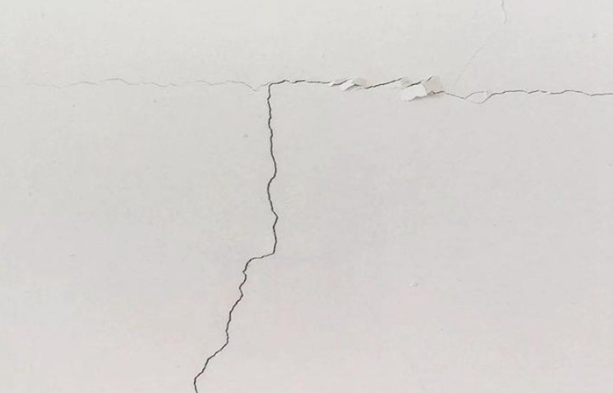

While chopped fiberglass strands for concrete offer many advantages over traditional steel rebars, they are not a direct replacement for steel in all applications. Fiberglass is particularly effective in controlling cracking and improving the tensile strength of concrete, but it does not provide the same level of compressive strength as steel. In most cases, a combination of fiberglass chopped strands and steel rebars is used to achieve the optimal balance of strength, durability, and cost.

Niumaterial has extensive experience in providing customized solutions that combine the strengths of our chopped fiberglass strands for concrete with steel rebars. For example, in a large commercial building project, our team worked closely with the client’s engineering team to design a hybrid reinforcement system. This system reduced the overall project cost by 15% while maintaining the required structural performance.

Our chopped fiberglass strands for concrete are engineered with a specific aspect ratio and fiber distribution pattern to optimize stress distribution within the concrete. In a scientific study conducted in collaboration with a leading university, our strands were shown to increase the ductility of concrete by 60%, allowing structures to deform more safely under extreme loads without sudden failure.

Niumaterial is proud to be the leading manufacturer of chopped glass strand for concrete in China. With over 20 years of experience in the fiberglass industry and 12 years of exporting, we have a reputation for providing high-quality products and excellent customer service.

Quality Assurance: We are committed to providing our customers with the highest quality chopped glass strand for concrete. Our products follow strict quality control standards and are rigorously tested to ensure compliance with international standards.

Each batch of chopped glass strand for concrete undergoes 12 different quality tests, including tensile strength testing, length uniformity checks, and chemical composition analysis. Our products comply with CE, ISO9001, REACH, SGS standards. , giving customers peace of mind about product quality.

Customer-centric philosophy: At niumaterial, we put our customers first. We understand the importance of on-time delivery, quality control, and competitive pricing, and work closely with our customers to ensure their needs are met. Our dedicated customer service team is available 24/7 to answer any questions or concerns you may have.

We currently serve customers in 126 countries, and these partnerships are a testament to the trust and confidence our customers have in our chopped glass fiber strands for concrete and our commitment to excellence.

If you have any questions

Please contact us for free consultation and product quotation

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~