- infor1@fiberglassyn.com

- +86-13933702587

As a manufacturer at Niumaterial, a company with over two decades of dedication to the fiberglass industry, I’ve witnessed firsthand how fiberglass chopped strand mat (CSM) has revolutionized composite manufacturing—especially in boat building. From the rugged hulls of commercial fishing vessels to the sleek exteriors of luxury yachts, CSM has become the unsung hero behind some of the most durable marine structures. Yet, many in the industry still underestimate its potential or misunderstand how to maximize its benefits. In this blog, we’ll dive deep into what makes CSM a game-changer, address common misconceptions, and explore why it’s the preferred choice for savvy boat builders worldwide—including how our team at Niumaterial has perfected its production to meet the rigorous demands of global markets.

Imagine cruising through stormy seas in a vessel that withstands relentless waves, UV radiation, and the corrosive effects of saltwater. The secret behind such resilience? A strategic combination of material science and engineering—with chopped mat at its core. But let’s start with the basics: What exactly is CSM, and why does it dominate the marine composite landscape?

For over 12 years, we’ve exported chop strand mat fiberglass to manufacturers in Europe, Asia, and the Americas, supporting everything from small-scale DIY boat projects to large-scale commercial shipyards. Our clients often come to us with two primary concerns: “Is CSM strong enough for my application?” and “How does it compare to other fiberglass products?” These questions highlight a broader industry need for clarity on CSM’s capabilities, especially as competition in marine manufacturing intensifies.

Let’s confront the elephant in the room: Boat building is unforgiving. A single flaw in material selection can lead to costly repairs, safety hazards, or damaged reputations. That’s why understanding the nuances of csm 300 fiberglass, chop strand fiberglass roll applications, and compatibility with resins like epoxy isn’t just optional—it’s essential. In the sections below, we’ll unpack the six most critical questions about CSM, empowering you to make informed decisions that enhance both product quality and profitability.

A chopped strand mat is a non-woven composite of randomly oriented glass fibers, and Niumaterialversion takes this to the next level. We use premium E-glass fibers renowned for chemical resistance, paired with a binder that activates during curing to create a uniform, moldable structure. Unlike generic mats, our fiberglass chopped strand mat undergoes strict quality control at every step—from fiber diameter consistency to binder distribution—ensuring it conforms seamlessly to complex hull curves and minimizes voids during layup.

Well: yes – if it’s produced properly. CSM derives its strength from its unique fiber arrangement. Unlike woven fabrics, which have directional strength (higher strength in the warp and weft directions), CSM has isotropic strength, meaning it has strength in all directions. This makes it ideal for applications where hydrophobicity is applied from multiple angles, such as marine structures subjected to dynamic hydrodynamic forces.

Take our CSM 300 fiberglass, for example. The “300” refers to the weight per square meter (300 g/m²), a common specification in shipbuilding. This density achieves a balance of strength and flexibility, allowing the mat to absorb impact without cracking while maintaining a smooth surface finish. Of course, strength also depends on how you use it. Using CSM with the right resin (e.g. epoxy) is key to ensuring the correct layup technique as well as controlling the reinforcement conditions. At Niumaterial, we perform rigorous testing to ensure our mats meet international standards (ISO, ASTM), so you can trust their performance even in the most advanced marine environments.

Niumaterial’s chopped strand mats are designed for high strength. Our CSM 300 glass fiber, weighing 300 g/m², provides balanced isotropic strength, which is critical for marine applications where forces come from all directions. Unlike directional woven fabrics, our mats feature random fiber joints for even distribution, reducing the risk of cracking. Plus, our in-house testing lab (certified to ISO and ASTM standards) ensures that every roll of mat meets or exceeds industry strength benchmarks, giving boat builders confidence in the harsh marine environment.

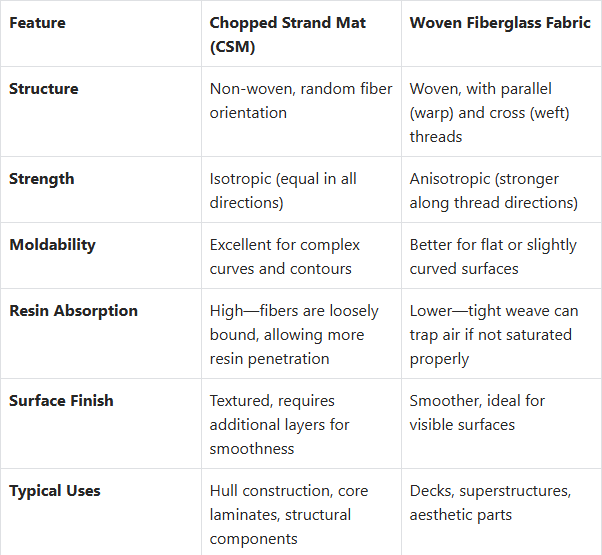

This is a question we hear often, and the answer lies in their structural and functional differences:

In boat building, the choice often comes down to the part’s geometry and performance needs. Hull bottoms, which face constant impact and need uniform strength, are perfect for CSM. Woven fabrics, on the other hand, might be used for decking where a cleaner finish is required. Many builders use a combination of both to optimize strength and cost—a strategy our technical team is happy to help clients refine.

Absolutely – and in many cases, it’s the preferred combination. Epoxies are known for their high tensile strength, chemical resistance, and excellent adhesion to glass fibers, making them a natural choice for chopped glass fiber roll applications. Unlike polyester resins, which are brittle and less resistant to UV damage, epoxies are able to form bonds that can withstand the repeated stresses of the marine environment. Niumaterial chopped glass fiber rolls are optimized for epoxy compatibility. The adhesive formulation of our mats promotes rapid wet-out, which reduces resin waste and bubbles during the lamination process. We have tested our CSM with major epoxy brands and have proven its ability to enhance bond strength and chemical resistance – critical for seawater durability. Customers who use our mats report a smoother layup process with less rework due to the uniform thickness and even fiber distribution of our mats.

In the boat building industry, CSM is more than just a material; it’s a foundational component of the laminate system. Here’s how it’s typically used:

Hull Construction: Layers of CSM are combined with resin to form the primary structural skin. Thicker mats (like 600g/m²) are used for high-load areas, while lighter mats (300g/m²) are ideal for non-structural parts.

Core Bonding: CSM is used to bond core materials (like foam or balsa wood) to skins, creating stiff, lightweight sandwich structures.

Repairs: Damaged areas can be patched with CSM, providing a strong, seamless fix that matches the original laminate properties.

For boat builders, Niumaterial’s CSM is a foundational tool. Whether you’re hand-laying a hull or using RTM processes, our mats deliver uniform strength and easy moldability. Our csm 300 fiberglass is a popular choice for mid-load areas, offering a sweet spot of affordability and performance, while heavier mats suit high-stress zones. Plus, our global logistics network ensures timely delivery—critical for projects where downtime equals lost revenue.

The versatility of chop strand mat fiberglass is one of its biggest advantages. In addition to boat building, it’s used in:

But let’s focus on marine applications, where CSM truly shines. From creating the initial hull laminate to repairing damaged structures, CSM provides a cost-effective way to build strong, watertight components. Its ability to conform to double-curved surfaces makes it indispensable for complex hull designs, while its resistance to moisture and chemicals ensures long-lasting performance—even in saltwater environments.

As the largest fiberglass chopped strand mat manufacturer in northern China, we don’t just produce mats—we engineer solutions. Here’s what sets us apart:

20 Years of Specialization: We’ve honed our processes to deliver consistent quality, from fiber selection to binder formulation.

Customer-Centric Approach: Unlike market-oriented suppliers who prioritize trends over needs, we work directly with clients like Hans to solve specific challenges—whether it’s customizing mat weight for a unique project or ensuring on-time delivery for a tight schedule.

Global Expertise: With a decade of supplying to top U.S. companies, we understand international standards, logistics, and the importance of reliable partnerships in global supply chains.

End-to-End Control: Our 200+ employee team manages every step of production, from melting glass furnaces to final quality chec

In marine manufacturing, the right materials aren’t just components—they’re competitive advantages. Niumaterial’s chopped mat delivers the strength, consistency, and support you need to build boats that outlast storms, outperform expectations, and outshine competitors. With 20 years of dedication to fiberglass excellence and a client-first approach, we’re not just suppliers; we’re partners in your success.

Ready to experience the Niumaterial difference? Whether you need csm 300 fiberglass for a standard hull or a custom solution for a luxury yacht, our team is here to help. Contact us today and discover why leading boat builders worldwide trust our chop strand mat fiberglass to turn their designs into durable, market-leading vessels. The sea is demanding—your materials shouldn’t be.

Stay connected for more insights on optimizing composite processes with Niumaterial’s CSM. From layup tips to resin compatibility guides, we’re committed to empowering your success in every project.

If you have any questions

Please contact us for free consultation and product quotation

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~