- infor1@fiberglassyn.com

- +86-13933702587

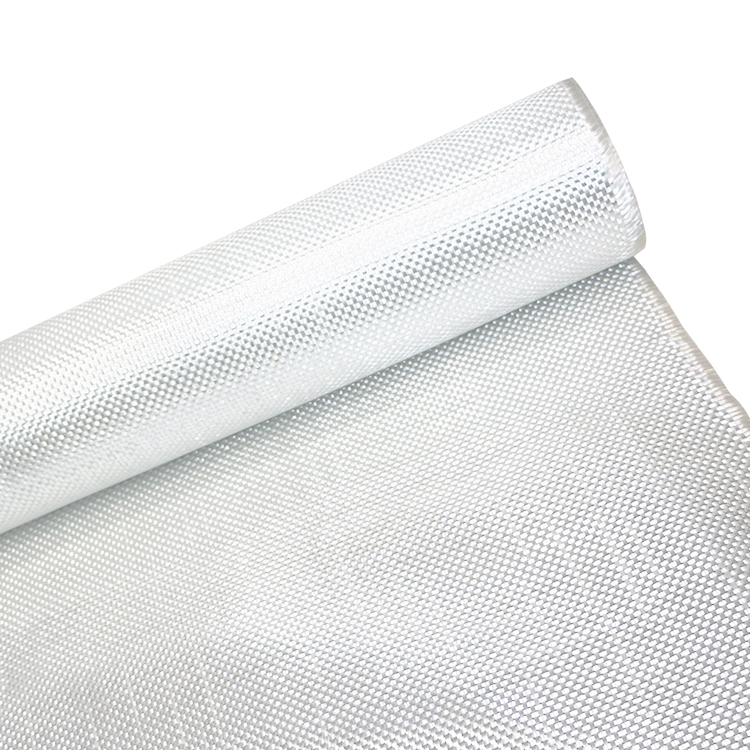

In modern industry and construction, fiberglass woven roving is a high-performance reinforcement material that is favored for its excellent mechanical properties and durability. As an industry-leading manufacturer, Niumaterial is committed to providing high-quality, customized fiberglass woven roving solutions to meet the needs of different projects. This article will explore in detail the characteristics and applicable scenarios of plain, twill and satin woven woven fabrics, and deeply analyze the application advantages of woven fabrics in winding pipes, shipbuilding, FRP reinforcement and swimming pool manufacturing. In addition, we will discuss the key factors when choosing fiberglass woven fabrics and explain why choosing Niumaterial woven fabrics is the best choice.

Features:

Application scenarios:

Features:

Application scenarios:

Features:

Application scenarios:

Wrapped pipes are a composite material pipe made by a continuous winding process and are widely used in petroleum, chemical, municipal engineering and other fields. In order to ensure the strength and durability of the pipe, it is essential to choose the right reinforcement material. Fiberglass woven roving has become the preferred material for manufacturing winding pipes due to its excellent performance.

Specific advantages:

Shipbuilding has extremely strict requirements on materials, especially the strength and durability of the hull structure. As a high-performance reinforcement material, glass fiber woven fabric is widely used in shipbuilding, providing reliable structural support and protective layer.

Specific advantages:

FRP (fiberglass reinforced plastic) is a widely used composite material with the characteristics of high strength, light weight and corrosion resistance. As an important reinforcement material for FRP, fiberglass woven roving significantly improves the performance of composite materials.

Specific advantages:

The construction of swimming pools has very high requirements for materials, especially the strength and durability of the pool body. As a high-performance reinforcement material, glass fiber woven roving is widely used in the construction of swimming pools, providing reliable structural support and protective layer.

Specific advantages:

Choosing the right glass fiber woven roving is essential to the success of the project. Here are a few key factors to help you make a wise choice:

Choose the right weave type (plain, twill or satin) according to the specific project requirements to ensure optimal performance and results.

Pay attention to the mechanical properties of the woven fabric, such as tensile strength, modulus and elasticity, to ensure that it can meet the strength and stability requirements of the project.

Choose woven fabric with good durability and corrosion resistance, especially when used in humid, hot or corrosive environments.

Consider the ease of construction of the woven fabric, including the difficulty of cutting, laying and bonding, to ensure an efficient and smooth construction process.

Choose woven fabric that meets international environmental standards, uses environmentally friendly materials, reduces VOC emissions, and meets the sustainable development requirements of modern construction and industrial fields.

Consider the cost and performance of the woven fabric comprehensively, and choose the most cost-effective product to ensure that the project achieves the best results within the budget.

As an industry-leading manufacturer, Niumaterial has launched glass fiber woven fabric with unique advantages with its excellent quality and innovative technology. Here are a few key reasons that highlight the unique advantages of Niumaterial compared to other manufacturers:

Niumaterial strictly follows international quality standards to ensure that each batch of products reaches the highest level. The company has passed a number of certifications, including ISO 9001 quality management system certification, ASTM D3039 composite material tensile performance test standard and EN 13501-1 fire performance test standard.

With more than 20 years of technical accumulation and market experience, Niumaterial is well aware of customer needs and can provide the most appropriate solutions. It provides more than 1,000 tons of procurement services to more than 100 companies around the world each year, and is widely used in building reinforcement, pipeline repair and decoration and other fields.

In summary, fiberglass woven roving has become the preferred material for manufacturing winding pipes, shipbuilding, FRP reinforcement and swimming pool manufacturing due to its excellent strength, durability and corrosion resistance. As a leading manufacturer in the industry, Niumaterial provides you with perfect solutions with its excellent quality and innovative technology. I hope this article can provide you with valuable reference and help you make a wise choice. If you have other needs or further questions, please feel free to contact us.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a header to begin generating the table of contents Big 5 Global – Connecting the Future of Global Construction As a

Table of Contents Add a header to begin generating the table of contents Introduce In the composite materials sector, where strength, versatility and reliability are

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~