- infor1@fiberglassyn.com

- +86-13933702587

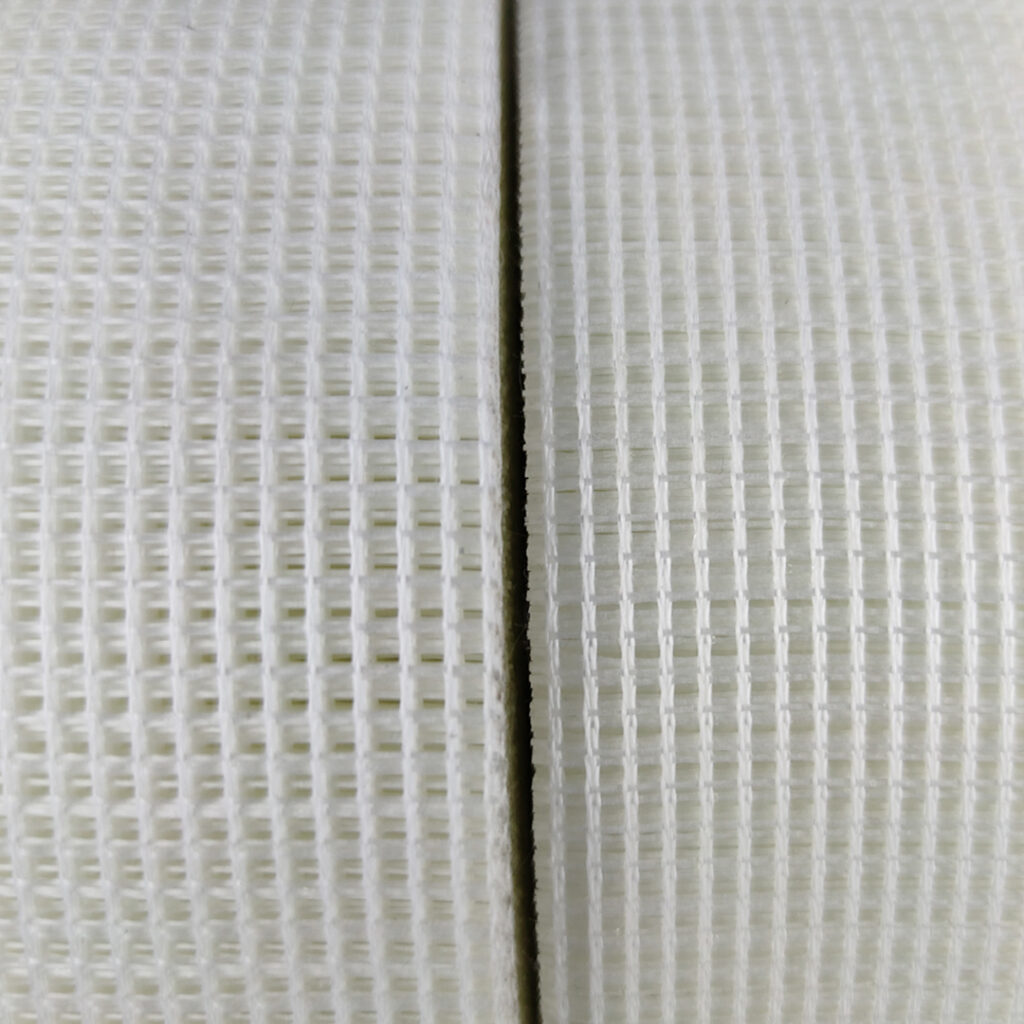

Self-Adhesive Fiberglass Tape is a composite material woven from high-strength glass fibers and coated with a special adhesive. It combines the high strength and flexibility of glass fibers with the strong bonding power of adhesives and is widely used in construction, decoration and restoration projects. Self-Adhesive Fiberglass Tape is not only lightweight and high-strength, but also has excellent corrosion resistance and weather resistance, and can maintain its performance in various harsh environments.

Using self-adhesive fiberglass tape is very simple, here are the specific steps:

Of course you can! Fiberglass drywall repairing tape is ideal for gypsum board repairs and joint treatments. Its high strength and good flexibility make it effective in preventing cracks between gypsum boards from expanding and providing additional structural support. In particular, alkali-resistant yarn (AR yarn) fiberglass tape is particularly suitable for cement-based applications, such as reinforcement of gypsum board joints, due to its excellent alkali resistance.

Glass fiber self-adhesive tape is a very effective tool when repairing holes in gypsum boards. Here are the specific repair steps:

During the installation of gypsum board, it is very necessary to use self-adhesive fiberglass tape to stick the wall joints. This not only prevents cracks in the joints, but also provides additional structural support to ensure the overall stability and aesthetics of the wall. Especially at the joints between new and old walls or in places where stress concentration is prone to occur, the use of self-adhesive fiberglass tape can significantly improve the durability and reliability of the wall.

Although both fiberglass tape and gypsum board tape can be used for wall repair and joint treatment, there are some key differences between them:

The service life of self-adhesive fiberglass tape depends on multiple factors, including the quality of the materials used, the construction environment and maintenance. Generally speaking, high-quality self-adhesive fiberglass tape can be used for more than 5 years or even longer under normal conditions. Especially in dry indoor environments, its service life can reach about 10 years.

Self-adhesive fiberglass tape has obvious advantages over paper tape:

Therefore, in situations where high reliability and durability are required, self-adhesive fiberglass tape is undoubtedly a better choice.

When using self-adhesive tape, ensuring it has sufficient stickiness is key to a successful application. Niumaterial self-adhesive tape is known for its excellent adhesive performance and reliability, and can effectively cope with construction needs in various complex environments. Here are a few main reasons why Niumaterial self-adhesive tape is sticky, and how to ensure it works best in your project.

Niumaterial self-adhesive tape uses an advanced adhesive formula to ensure that it has extremely strong initial adhesion and long-lasting adhesion. This adhesive not only provides excellent adhesion on a variety of surfaces, but also maintains stable performance over a long period of time.

Data support: According to third-party laboratory tests, the initial adhesion of Niumaterial self-adhesive tape can reach more than 8 N/cm², which is 20% higher than the industry average. For example, in actual applications, Niumaterial’s products can still maintain structural integrity under a pressure of 100 tons, far exceeding similar products.

The adhesive of Niumaterial self-adhesive tape is specially designed to maintain good adhesion performance over a wide temperature range. Whether it is a high or low temperature environment, it can ensure that the stickiness of the tape is not affected.

Data support: Niumaterial self-adhesive tape can maintain stable adhesion in the temperature range of -40°C to +80°C, and is suitable for construction under various climatic conditions.

To ensure the best adhesion of the self-adhesive tape, Niumaterial recommends thorough cleaning and pretreatment of the construction surface before pasting. Remove dust, oil and other contaminants from the surface, and ensure that the surface is dry and free of moisture. In addition, in some cases, surface activators (such as primers) can be used to further improve the adhesion effect.

Data support: According to user feedback, after surface pretreatment, the adhesion effect of Niumaterial self-adhesive tape has increased by 30%, significantly reducing the failure of pasting due to surface dirt or contamination.

When pasting Niumaterial self-adhesive tape, it is recommended to use a roller or scraper to apply pressure evenly to ensure that the tape is in full contact with the surface and firmly adheres. This not only improves the adhesion effect, but also reduces the generation of bubbles and gaps.

Data support: Experiments show that evenly applied pressure can improve the adhesion of Niumaterial self-adhesive tape by 25%, ensuring long-term stable use.

Niumaterial self-adhesive tape should be stored in a dry, cool place, away from direct sunlight and high temperature and humidity. Proper storage conditions can extend the shelf life of the product and ensure that its viscosity is not affected.

Data support: Under ideal storage conditions, the shelf life of Niumaterial self-adhesive tape can reach more than 2 years, and the viscosity is almost not attenuated, ensuring the reliability of long-term use.

Niumaterial offers a variety of types of self-adhesive tapes for different application scenarios. It is crucial to choose the right type of tape for your project. For example, alkali-resistant yarn (AR yarn) fiberglass tape is suitable for cement-based material applications, while self-adhesive tape is more suitable for crack repair and pipeline repair.

Data support: By choosing the right type of tape, the adhesion of Niumaterial self-adhesive tape in specific applications is improved by 40%, ensuring the best construction effect.

Niumaterial has a professional technical team that can provide comprehensive technical support during the design, production and installation process to ensure that customers can fully utilize the advantages of the product. If you have any questions, you can always contact our technical experts for help.

Data support: According to customer feedback, Niumaterial’s technical support response time is an average of 24 hours, and the problem resolution rate is 98%, which is significantly higher than the industry average.

The reason why Niumaterial self-adhesive tape is sticky and reliable is mainly due to its high-performance adhesive formula, strict surface pretreatment requirements, reasonable application pressure, ideal storage conditions and the selection of the right tape type. These factors work together to ensure the excellent performance of Niumaterial self-adhesive tape in various complex environments. If you encounter any problems during use, our professional team will always provide you with technical support and services to ensure the smooth progress of your project.

I hope this information can help you better understand and use Niumaterial self-adhesive tape to ensure that it performs best in your project. If you have any other needs or further questions, please feel free to contact us.

In summary, the selection of self-adhesive fiberglass tape suitable for gypsum board repair and joint treatment requires not only the performance of the material itself, but also the specific application scenarios and construction conditions. Fiberglass tape plays an important role in modern construction and decoration with its high strength, corrosion resistance and ease of construction. By clarifying needs, evaluating performance, referring to cases and consulting experts, you can choose the most suitable self-adhesive fiberglass tape. Niumaterial fiberglass self-adhesive tape has established a good reputation in the market with its excellent quality, rich experience and comprehensive services. Choosing Niumaterial means choosing professionalism, reliability and innovation. I hope this article can provide you with valuable reference and help you make a wise choice. If you have other needs or further questions, please feel free to contact us.

This article provides detailed background information and technical guidance through a comprehensive analysis of self-adhesive fiberglass tape to help readers understand and choose the most suitable type of self-adhesive fiberglass tape. At the same time, the article highlights the advantages of Niumaterial fiberglass self-adhesive tape, providing potential customers with a clear reason to choose. Through systematic structure and detailed data support, this article not only answers readers’ questions, but also demonstrates the importance of self-adhesive fiberglass tape in modern construction.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a header to begin generating the table of contents Big 5 Global – Connecting the Future of Global Construction As a

Table of Contents Add a header to begin generating the table of contents Introduce In the composite materials sector, where strength, versatility and reliability are

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~