- infor1@fiberglassyn.com

- +86-13933702587

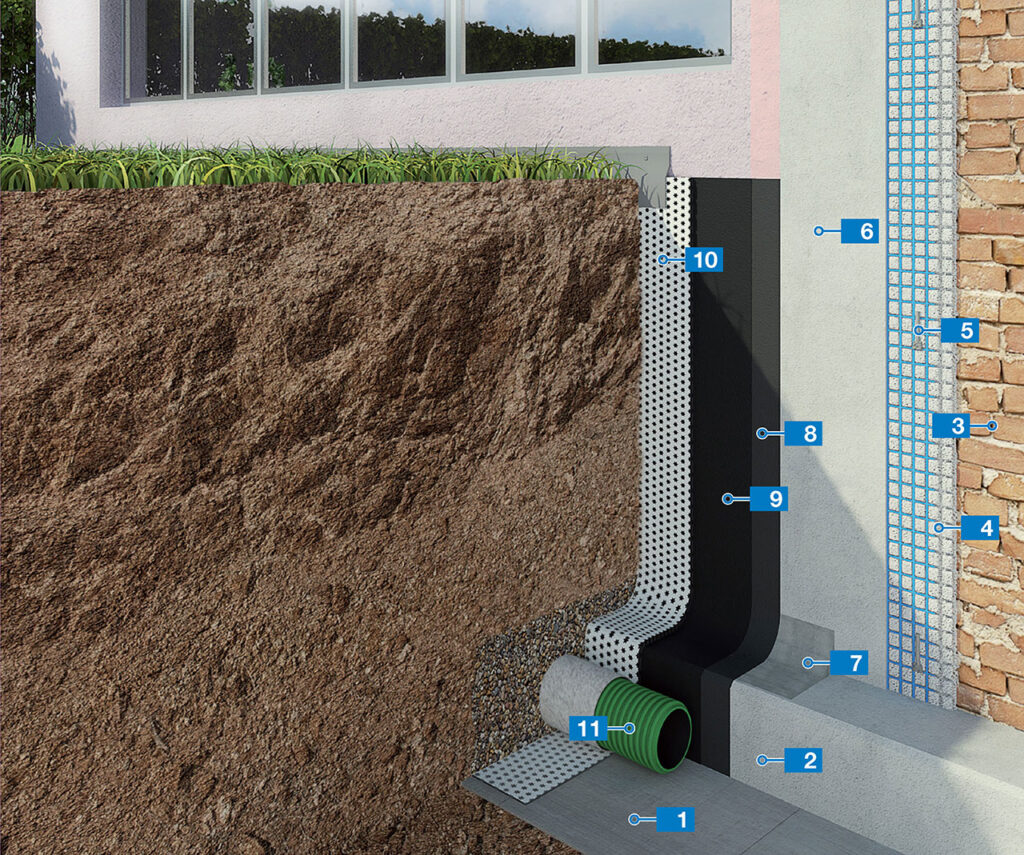

The construction industry is very important in the process of urbanization. However, the quality of buildings is not only related to their service life, but also directly affects people’s quality of life and safety. Among the many factors that affect the quality of buildings, waterproofing is particularly prominent. As a key component of building safety, waterproof materials play an irreplaceable role in ensuring the functionality of buildings and extending their service life. In recent years, with the advancement of new material technology, more and more high-performance waterproof materials have been developed. Among them, glass fiber (referred to as glass fiber) as a new type of waterproof material has attracted much attention due to its unique properties. The application of fiberglass products has shown great potential in the field of waterproofing with their excellent mechanical strength, chemical stability and aging resistance.

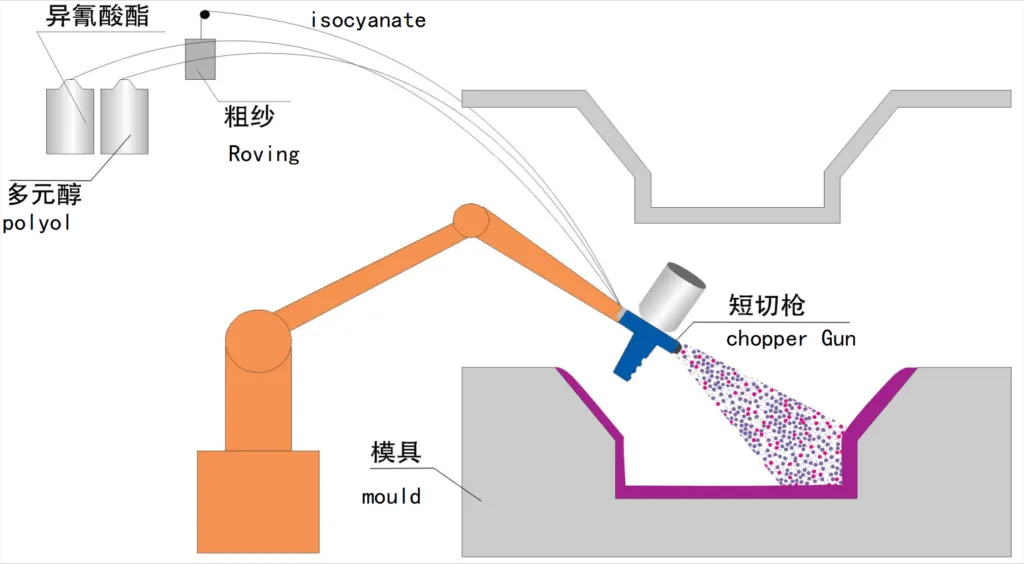

Glass fiber (abbreviated as fiberglass) is an extremely fine fiber formed by melting silicate through high-speed rotation or drawing process. It has the characteristics of light weight, high strength, corrosion resistance and good insulation. According to different production processes, raw materials and uses, fiberglass products can be divided into the following categories:

In some special environments, such as bridges and tunnels, waterproofing is not only related to the safety of buildings, but may also affect the normal operation of transportation systems. The application of glass fiber materials in these special environments has the following characteristics:

Fiberglass materials have high tensile strength and can effectively enhance the structural stability of the waterproof layer and prevent damage caused by external forces. Glass fiber is not corroded by most chemicals and is suitable for a variety of environmental conditions, which prolongs the service life of waterproof materials. Whether in extreme high or low temperature conditions, glass fiber can maintain stable performance, is not easy to age, and is suitable for applications in various climate environments. At the same time, glass fiber can be used in combination with a variety of substrates, such as asphalt, polymers, etc., to form composite materials with different properties to meet diverse waterproofing needs.

In the field of glass fiber products, Niumaterial stands out as a high-quality glass fiber manufacturer with its excellent product quality and advanced production technology. Aiswix is committed to providing customers with high-quality glass fiber materials, covering a variety of product types from glass fiber mesh cloth to reinforced composite materials, which are widely used in roof waterproofing, underground structure waterproofing, and waterproofing treatment in special environments. Aiswix strictly implements ISO quality management system standards during the production process to ensure that each batch of products reaches the best performance level. The company has a dedicated quality inspection laboratory to conduct comprehensive inspections on products before leaving the factory, including tensile strength tests, weather resistance experiments, etc., to ensure stable and reliable product quality.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a header to begin generating the table of contents Big 5 Global – Connecting the Future of Global Construction As a

Table of Contents Add a header to begin generating the table of contents Introduce In the composite materials sector, where strength, versatility and reliability are

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~