- infor1@fiberglassyn.com

- +86-13933702587

In construction and industry, choosing the right materials is crucial to the successful implementation of a project. In terms of structural reinforcement and waterproofing, fiberglass mesh and polyester mesh are common building materials that have attracted much attention. Each of them has unique characteristics and application areas, but all factors need to be considered when selecting.

This article will take an in-depth look at the performance comparison of Alkali Resistant Mesh and polyester mesh and provide readers with guidance on making an informed choice in their specific project. Through a detailed analysis of these two materials, Niumaterial aims to help industry professionals and decision-makers better understand their advantages and disadvantages in order to achieve the best results in practical applications. Therefore, this article aims to provide a comprehensive perspective on material selection to meet the needs of different projects, thus driving progress in the construction and industrial fields.

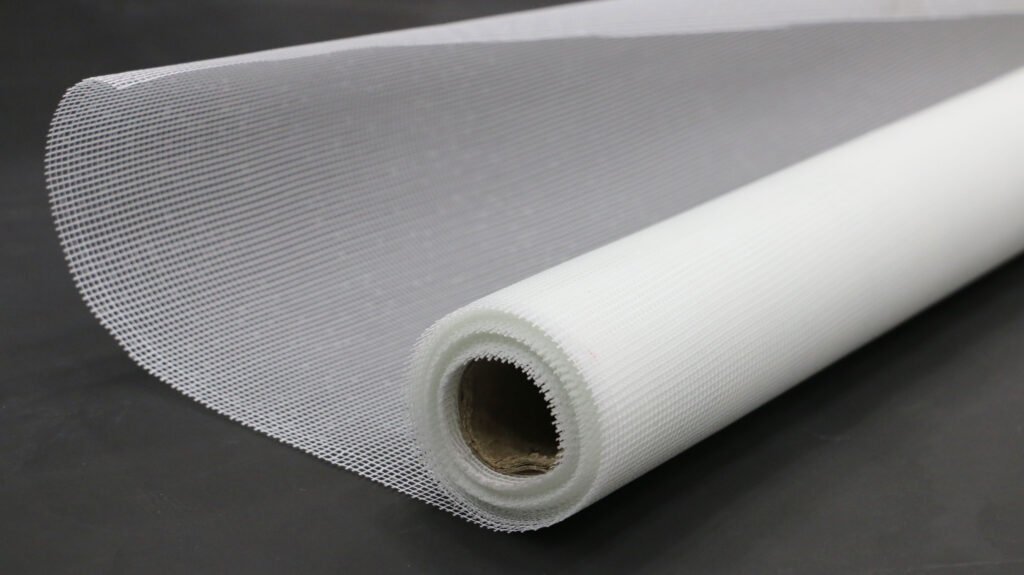

Alkali resistant mesh tape is a material widely used in construction and industry, and its unique properties make it useful in a variety of applications. First, we will provide an overview of the characteristics of fiberglass mesh and gain insight into its composition and physical properties.

Fiberglass mesh is primarily composed of glass fibers, which gives it excellent strength and durability. The high tensile strength of glass fiber makes this mesh perform well in scenarios with high strength requirements such as structural reinforcement. In addition, its lightweight nature makes installation and transportation easier. In terms of physical properties, AR Fiberglass Mesh generally has excellent corrosion resistance and weather resistance, which allows it to maintain stable performance under various environmental conditions.

AR-glass fiber mesh has many applications in the construction field, including interior and exterior wall insulation, wall reinforcement, roof waterproofing, gypsum board and marble backing.

As an excellent thermal insulation material, fiberglass mesh is often used in the insulation system of interior and exterior walls. By embedding fiberglass mesh into the insulation layer, the insulation performance of the wall can be effectively improved. Its lightweight and flexible characteristics make construction more convenient, while ensuring the firm bonding between the insulation material and the wall, improving the overall insulation effect.

Fiberglass mesh plays an important role in the reinforcement of wall structures. By bonding the mesh cloth to the wall surface, the tensile strength and crack resistance of the wall can be effectively improved. This application is often used to strengthen the structure of old buildings to make them more able to withstand the impact of the external environment and extend their service life.

In the field of roof waterproofing, concrete mesh cloth is often used together with waterproof coatings. Laying mesh cloth on top of the paint layer can effectively enhance the waterproof performance of the roof. Its weather resistance and corrosion resistance make it stable in different climate conditions, providing reliable waterproof protection.

In the construction of gypsum board, fiberglass mesh is often used to enhance the overall performance of the gypsum board. By embedding mesh cloth into the gypsum board, the tensile and impact resistance of the gypsum board can be improved and the occurrence of cracks can be prevented. This has significant effects in terms of wall decoration and sound insulation.

In the back-paving process of marble, fiberglass mesh cloth is used as a reinforcing material. By bonding the mesh cloth to the back of the marble, it can effectively prevent cracks in the marble during use and enhance its overall tensile properties. This is of great significance to the long-term beauty and stability of marble.

These application areas demonstrate the versatility of fiberglass mesh in construction, providing reliable support and reinforcement for different aspects of the project.

Excellent strength: Concrete reinforcing mesh has excellent tensile and flexural strength, making it excellent in areas such as structural reinforcement and wall reinforcement. Its high strength enables it to effectively improve the overall load-bearing capacity of the structure during reinforcement projects.

Corrosion resistance: Fiberglass mesh exhibits good corrosion resistance and is not easily eroded by chemicals and the environment, so it is suitable for various construction environments.

Good adhesion: Fiberglass mesh can usually be fully bonded to various base materials to ensure a tight connection between the reinforcement material and the wall and improve the reinforcement effect.

Relatively Brittle: Despite its superior strength, fiberglass mesh may exhibit relatively brittle characteristics in some situations and may not be as suitable as other materials for certain applications that require flexible handling.

Sensitivity to high temperatures: In high temperature environments, the performance of eifs fiberglass mesh may be affected to a certain extent. Therefore, use in high temperature environments needs to be carefully considered and other high temperature resistant materials may need to be used.

By analyzing the characteristics, application areas, advantages and disadvantages of fiberglass mesh, we can have a more comprehensive understanding of the scope and limitations of this material. In actual projects, knowing this information will help decision-makers more accurately select building materials suitable for their needs.

As another common building material, polyester mesh has unique properties and has gradually found wide applications in the construction and industrial fields. We will give a detailed description of polyester mesh cloth from three aspects: characteristics overview, application fields and analysis of advantages and disadvantages.

The main component of polyester mesh cloth is polyester fiber, which is lightweight, flexible, and corrosion-resistant. Compared with other materials, polyester fiber has higher tensile strength, which provides a good performance basis for polyester mesh cloth in fields such as structural reinforcement. In addition, polyester mesh generally has good UV resistance and can remain stable in outdoor environments for a long time.

Polyester mesh plays an active role in the wall insulation system. Its light weight and flexibility make it more flexible during the construction process of the insulation layer. At the same time, its high tensile strength helps to improve the stability of the insulation layer and increase the insulation effect of the wall.

Polyester mesh also plays a key role in cement mortar reinforcement. By embedding mesh cloth in cement mortar, the tensile properties of the structure can be effectively improved, the formation of cracks can be prevented, and the overall stability of the building can be enhanced.

Polyester mesh is often used in roof waterproofing systems, in combination with waterproof coatings. Its good corrosion resistance and UV resistance enable it to maintain its waterproofing effect even if the roof is exposed to the natural environment for a long time.

In the field of floor paving, polyester mesh cloth can be used to strengthen the base layer of ceramic tiles, marble and other materials. This helps prevent the floor material from cracking or deforming during use, increasing the life of the floor.

High tensile strength: The polyester fiber of polyester mesh has high tensile strength, making it excellent in structural reinforcement and reinforcement.

Lightweight and flexible: The relatively lightweight nature makes it more flexible during construction, and its flexibility helps adapt to different shapes of surfaces.

Relatively poor high temperature resistance: Compared with fiberglass mesh, polyester mesh has poorer high temperature resistance, so its application in high temperature environments needs to be carefully considered.

May be affected by UV rays: Despite its good UV resistance, long-term exposure to strong UV rays may affect its performance.

By analyzing the characteristics, application fields, advantages and disadvantages of polyester mesh, we can have a more comprehensive understanding of the scope and limitations of this material, and provide clearer guidance for project selection.

Fiberglass mesh and polyester mesh are two options that are highly considered when choosing the right building materials for a particular project. This section will provide you with guidance on selecting fiberglass mesh from both project needs and cost-effectiveness to ensure informed decisions in different scenarios.

If the project has high strength requirements for reinforced structures, especially in terms of load-bearing capacity improvement and structural reinforcement, external rendering mesh is a superior choice. Its excellent strength can effectively cope with demanding structural engineering.

Fiberglass mesh excels in projects that require long-term stability and durability. Its resistance to corrosion and weathering allows it to maintain stable performance in a variety of environmental conditions, ensuring projects have long-lasting results.

For some occasions that require flexible processing, such as projects that require reinforcement on curved surfaces or complex-shaped structures, fiber glass mesh has obvious advantages in flexibility and adaptability.

If the project needs to be used in a high temperature environment, you need to choose carefully. Although fiberglass mesh has relatively good heat resistance, under extreme high temperature conditions, other high temperature resistant materials may need to be considered.

In terms of initial investment, the price of fiber glass mesh fabric is relatively high. However, considering its excellent performance and long-term stability, it can be considered a long-term investment.

Due to the good durability of fiberglass mesh, its long-term maintenance costs are relatively low. The project does not require frequent repairs and replacements during its service life, reducing subsequent maintenance expenses.

Considering the light weight and flexibility of fiberglass mesh, its installation during the construction process is more convenient, thereby improving the overall efficiency of the project. This also helps reduce labor and time costs.

Due to the excellent performance of fiberglass mesh, its reinforcement effect is long-lasting and stable. Compared with some materials that have lower initial investment but shorter-term effects, fiberglass mesh provides more reliable results in the long term.

When selecting construction materials, project needs and cost-effectiveness are key factors in the decision-making process. Depending on the specific circumstances of the project, if strength, durability and long-term benefits are emphasized, choosing fiberglass mesh will be a rational option worth considering.

In terms of performance comparison, both fiberglass mesh and polyester mesh show unique advantages and applicable scenarios. Alkali Resistant Mesh stands out for its excellent strength, good durability and excellent performance in structural reinforcement.

In practical applications, we recommend comprehensive consideration based on specific project needs. If the project has higher requirements for structural strength, durability, etc., especially in projects that require long-term stability and excellent performance, it will be more sensible to choose concrete mesh cloth. For some projects that are sensitive to initial investment and require lightweight materials, polyester mesh may be a more affordable choice.

As construction technology and material technology continue to develop, we can expect more innovative building materials to emerge. Perhaps future materials will better balance lightweight and cost-effectiveness while maintaining strength and durability. This will provide more choices for the construction industry and promote more sustainable and efficient development in the engineering construction field.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a header to begin generating the table of contents Big 5 Global – Connecting the Future of Global Construction As a

Table of Contents Add a header to begin generating the table of contents Introduce In the composite materials sector, where strength, versatility and reliability are

You can leave your needs and contact information~and We can provide you with usage suggestions + product suitability analysis + free sample delivery!

Leave us your interest and contact information, and we’ll send you detailed information for your reference!

You can leave the specifications and contact information you need~ Our technicians will immediately organize the exclusive information for you and send it to your email!

You can leave your contact information here, and we will send you detailed specifications and application cases to make your purchase clearer~